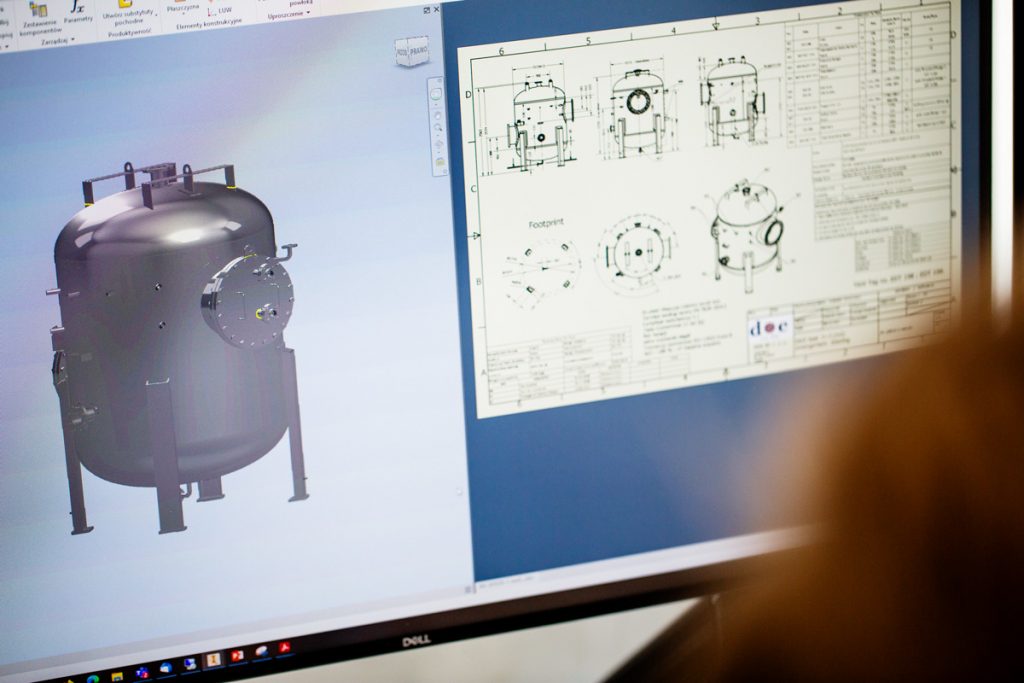

Design for marine and land classification

DOE has its own design office which makes custom designs on request. Every project is modelled in 3D which can be supplied on request to help with your own design. With a base of hundreds of executions we are ready to quickly provide suitable solution. Our designers have knowledge of most marine classification rules as well as PED directive for land applications.

Grundfos OEM

For many years DOE has been OEM partner for Grundfos solutions. It enables us to provide quick and affordable yet top of the line pumping systems. The cooperation is not exclusive, so other solutions are also possible – per client suggestion. By installing Grundfos pumps you are able to service them in every corner of the world using wide network of service points.

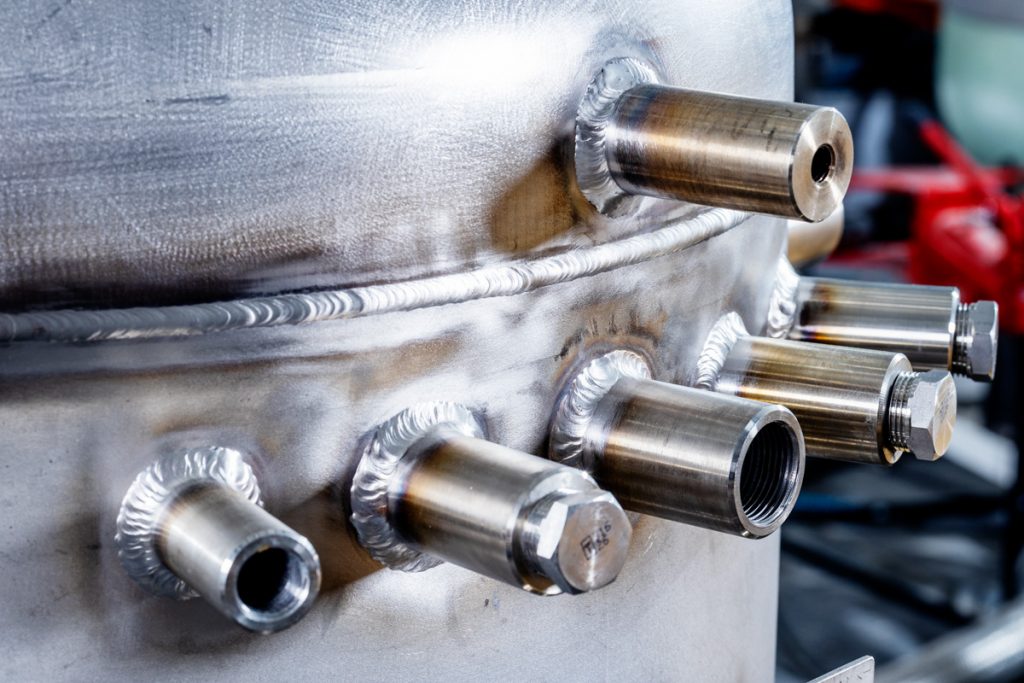

Highest quality of welds

Poland has been known for the most experienced welders in Europe and DOE has multi year experience in welding quality. Most of welds are made using TIG141 and MIG131/MAG135 method with standard of AISI316L and P355GH material. Proper after-welding finishing is applied depending on the final parameters of the anti-corrosion layer.

Attention to detail

High quality and working product is something obvious for us. As well as attention to details. With constant research and development works we are taking our products to another levels each year. Everyday DOE personnel seeks new technologies, thinks on how to improve products they build and improve their work so that DOE products can be more affordable yet better.

In-house WPQR and VT inspectors

High quality is DOE standard for years. With in-house Visual Test inspectors we are ready to deliver product which is made according to the project requirements without additional costs and unnecessary delay of external inspectors. Furthermore, our inspectors check the quality on every part of fabrication limiting even the slightest problems on daily basis.

Demanding applications

Most of the projects are the most demanding in the fields with welds close to each other on very tight designs. After many years of practice and research DOE has know-how and experience to weld even most complicated projects.