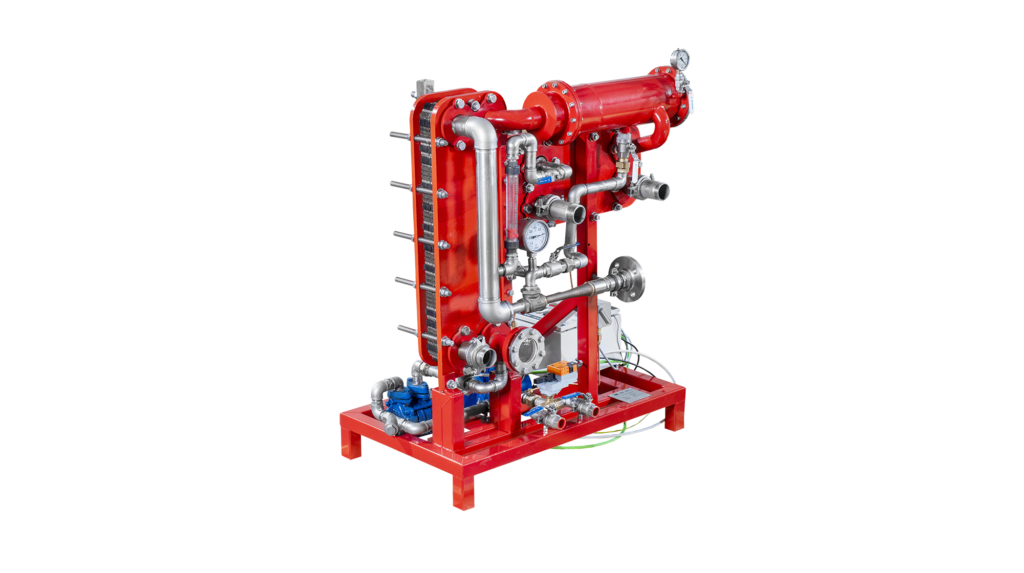

Plate heat exchangers are a type of heat transfer technology used to transfer heat between two fluids. They consist of a series of thin metal plates with channels through which the fluids flow, allowing for efficient heat exchange.

In a plate heat exchanger, the two fluids flow on opposite sides of the plates, and heat is transferred from one fluid to the other through the plates. The plates are designed to maximize the surface area available for heat transfer, and they are often corrugated or embossed to increase turbulence and improve heat transfer efficiency.

Plate heat exchangers are widely used in various industries, including HVAC, refrigeration, chemical processing, and power generation. They are often used for applications in which high heat transfer rates are required, such as in the cooling of hot fluids or the heating of cold fluids.

One of the advantages of plate heat exchangers is their high efficiency and compact size. They can transfer heat at a rate of several thousand watts per square meter, and their compact design allows for easy installation in tight spaces.

Additionally, plate heat exchangers are easy to maintain and can be easily disassembled for cleaning or repair. They also offer flexibility in terms of the flow rate, temperature, and pressure of the fluids being used, and can be customized to meet specific process requirements.

However, one of the limitations of plate heat exchangers is their susceptibility to fouling and clogging. Solid particles or contaminants in the fluid can accumulate on the surface of the plates, reducing their efficiency over time. Regular cleaning and maintenance of the heat exchanger are necessary to prevent these issues.

Overall, plate heat exchangers are a reliable and efficient technology for heat transfer in a variety of industrial applications.